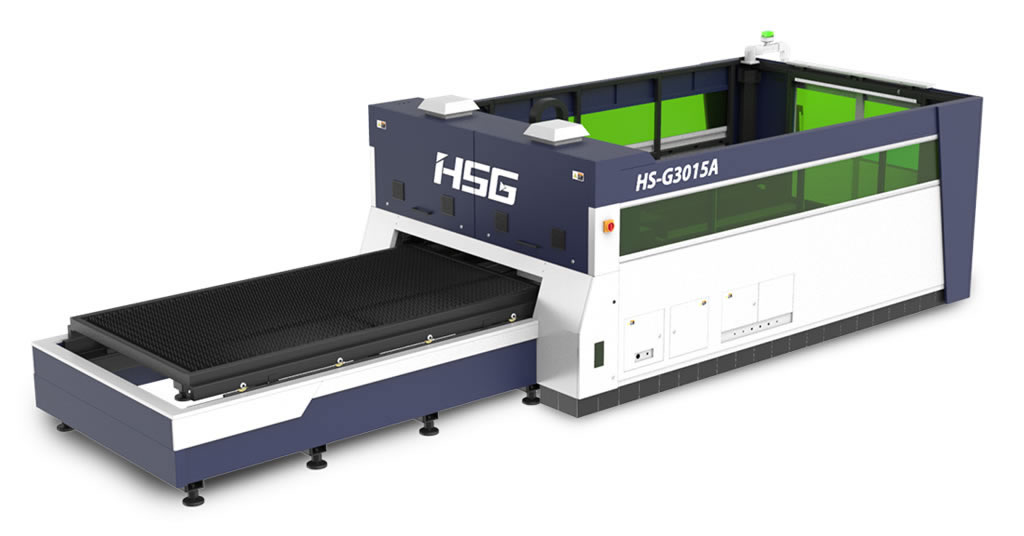

High speed fiber laser cutting system with interchangeable tables. Upper and lower tables save workspace and material feeding time. Provides an 8 second table interchange time, the fastest in the industry. Automatic height adjustment keeps the focal length constant ensuring the highest quality cuts.

This model of system is manufactured with highest quality German Servo Drive Motors and a Rack and Pinion drive systems. This system offers high precision and ultra-high speed acceleration speeds. This provides the manufacturing advantage for processing intricate shaped objects, with extremely high work efficiency that is 40% higher to some competitors systems.

The machine is supplied with cover protection. The energy from the laser source is supplied through the optical fiber in an armored cable. This design significantly simplifies machine operations and adjustments and increases machine reliability and its resistance to shocks in industrial operations. HSG manufacturers its systems that provide both stability and acceleration needed for high-speed precision machining.

Production Process of the Fiber Machine Chassis:

In the manufacturing process, the CNC machine chassis is first heated to a temperature of 600 °C and then gradually cooled down according to a preset scheme in a cooling container for the period of 24 hours. Its machining is then done in our special 26 ' long milling center. All welds are performed exclusively in a protective atmosphere. This Thermal-Stress Relieving process insures that the frame is free of any deformations and provides the rigidity needed for the highest precision, accuracy and cut quality.

The first manufacturer to use a cast aluminum beam manufactured by our 10-ton steel molding system providing superior rigidity. The weight is 50% lighter than a traditional welding iron gantry.

The first manufacturer to use a cast aluminum beam manufactured by our 10-ton steel molding system providing superior rigidity. The weight is 50% lighter than a traditional welding iron gantry.

In the manufacturing process, the CNC machine chassis is first heated to a temperature of 600 °C and then gradually cooled down according to a preset scheme in a cooling container for the period of 24 hours. Its machining is then done in our special 26 ' long milling center. All welds are performed exclusively in a protective atmosphere. This Thermal-Stress Relieving process insures that the frame is free of any deformations and provides the rigidity needed for the highest precision, accuracy and cut quality.

IPG LASER TECHNOLOGY PLATFORM

IPG LASER TECHNOLOGY PLATFORM

IPG’s unique technology platform allows our products to have higher output powers and superior beam quality at a lower cost than can be achieved by any other competing technology. Our proprietary designs are based around the innovative pumping techniques and high-performance components perfected by IPG over a 20-year period of intense investment and innovation.

German Alpha Wittenstein

German Alpha Wittenstein

Precision and performance.

The correct rack & precision drive system is an essential component in realizing your machines highest performance and cutting quality. HSG machines offers the finest class of German rack & pinions helical drive systems.

The right Rack for all Requirements

The correct rack and precision drive system is an essential component in realizing your machine cutting quality. WITTENSTEIN alpha offers the finest class of Rack & Pinions.

Technical Parameters:

| Processing Area: | 118 " x 59 " |

| Max.Traverse Speed: | 5512 ipm |

| Max. accelerated: | 1.2G |

| X/Y Positioning Accuracy: | ±0.001 " |

| X/Y Repeated Positioning Accuracy: | ±0.001 " |

| Power supply: | 380V 50Hz |

| Laser power: | 1000W-3000W |

| Machine Weight: | 16,535 lbs. |

| Machine dimensions: | 335" L x 114" W x 75" H |