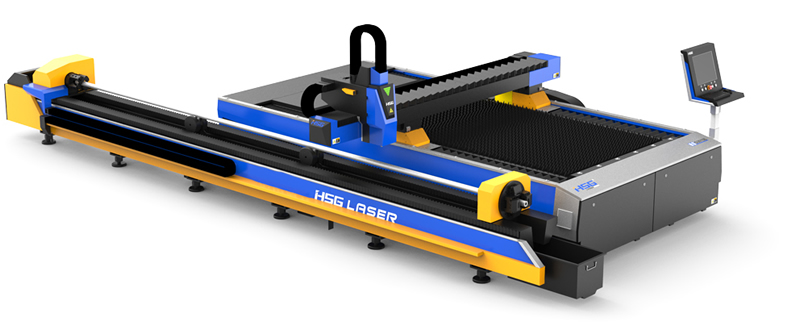

This comprehensive system solution offers both plate and pipe cutting capabilities. Highly versatile cutting solution for multiple shapes of pipe or tubing: square, round, oval, D-shaped and polygon.

Protective Cover: Optional

Designed for processing material with a length of up to 236 inches and a diameter not to exceed 7.87 inches. Sheet material processing size of 118 inches in length by 59 inches in width. This machine is enclosed with a safety protective cover.

This model of system is based on the popular HS-G3015C table design. Manufactured with servo drive motors and a helical rack and a pinion drive system. This system offers high precision of 0.05 mm and an ultra-high speed acceleration speed of 1.5 G. This provides the manufacturing advantage for processing intricate shaped objects, as the work efficiency is 40% higher compared to the M-series. The system is equipped with a fixed table with a 118 inch x 59 inch process working area.

The machine is supplied with cover protection. The energy from the laser source is not supplied to the place of cut by a mirror system as it was with the now obsolete CO2 lasers, but through an optical fiber in an armored cable. This design significantly simplifies machine operations and adjustments and increases machine reliability and its resistance to shocks in industrial operations.

The machine chassis is not to be sold separately; you can purchase it only together with the selected laser source.

Tube Cutting:

The tube cutting operation is designed for processing sections with a length up to but not exceeding 236 inches and a diameter of 7.87 inches. It uses an extremely precise principle of a tube laser; the material is fed through the rear chuck in the precisely controlled trolley through the front chuck to the cutting head. The rear chuck of both the F30 & F60 models features a pneumatic, i.e. automatic design. The front through chuck is mechanical and requires only to be set at the moment when you change the type of the section to be processed.

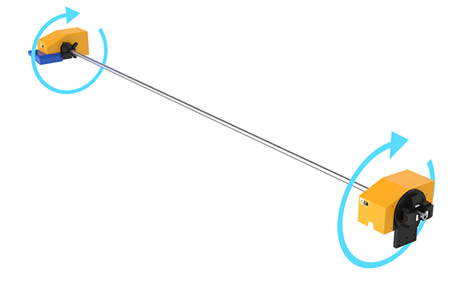

Dual-Axis Pipe Rotation:

Tubes and Pipes are turned on each end by a synchronized powered "Dual Rotation" drive system. Cutting 3 to 6 meter-long pipes are no longer limited to the slenderness ratio of 60:1. This ensures the highest cut quality accuracy and a product free of torque stress.

Tubes and Pipes are turned on each end by a synchronized powered "Dual Rotation" drive system. Cutting 3 to 6 meter-long pipes are no longer limited to the slenderness ratio of 60:1. This ensures the highest cut quality accuracy and a product free of torque stress.

IPG LASER TECHNOLOGY PLATFORM

IPG LASER TECHNOLOGY PLATFORM

IPG’s unique technology platform allows our products to have higher output powers and superior beam quality at a lower cost than can be achieved by any other competing technology. Our proprietary designs are based around the innovative pumping techniques and high-performance components perfected by IPG over a 20-year period of intense investment and innovation.

Dual Drive Single table design In the manufacturing process, the CNC machine chassis is first heated to a temperature of 600 °C and then gradually cooled down according to a preset scheme in a cooling container for the period of 24 hours. Its machining is then done in our special 26 ' long milling center. All welds are performed exclusively in a protective atmosphere. This Thermal-Stress Relieving process insures that the frame is free of any deformations and provides the rigidity needed for the highest precision, accuracy and cut quality.

In the manufacturing process, the CNC machine chassis is first heated to a temperature of 600 °C and then gradually cooled down according to a preset scheme in a cooling container for the period of 24 hours. Its machining is then done in our special 26 ' long milling center. All welds are performed exclusively in a protective atmosphere. This Thermal-Stress Relieving process insures that the frame is free of any deformations and provides the rigidity needed for the highest precision, accuracy and cut quality.

System Design Software: The machine is controlled by two programs: CypCut - for 2D cutting, and CypCut Tube for section cutting. Source data for surface cutting is with a dxf file format which can be generated from a variety of software programs. For section cutting, data are loaded in the format .iges. To prepare data for section cutting, Solidworks software is highly recommended and is fully compatable. We supply both the software programs with two licenses; one is installed directly in the machine, whereas the other is intended for possible data preparation independent of the machine.

Technical Parameters:

| Processing Area: | 118 " x 59 " (Optional |

| Pipe Processing Size (F30 up to 118"L): | .787" – 5.9" |

| Pipe Processing Size (F60 up to 236"L): | .787" – 5.9" |

| Max.Traverse Speed: | 2352 ipm |

| Max. accelerated: | 5G |

| X/Y Positioning Accuracy: | ±0.001 " |

| X/Y Repeated Positioning Accuracy: | ±0.001 " |

| Power supply: | 380V 50Hz |

| Laser power: | 750W-3000 Watt |

| Laser Source Manufacturer: | IPG |

| Machine Weight: | 22,046 lbs. |

| Machine dimensions: | 335" L x 158" W x 79" H |

| Drive System: | Panasonic Servo Motors |

| Transmission System: | German Helical Rack & Pinion |

| Graphic Formats: | DXF, PLT, Ai, LXD, GBX, NC G-Code |

| Protective Cover: Optional | Optional |