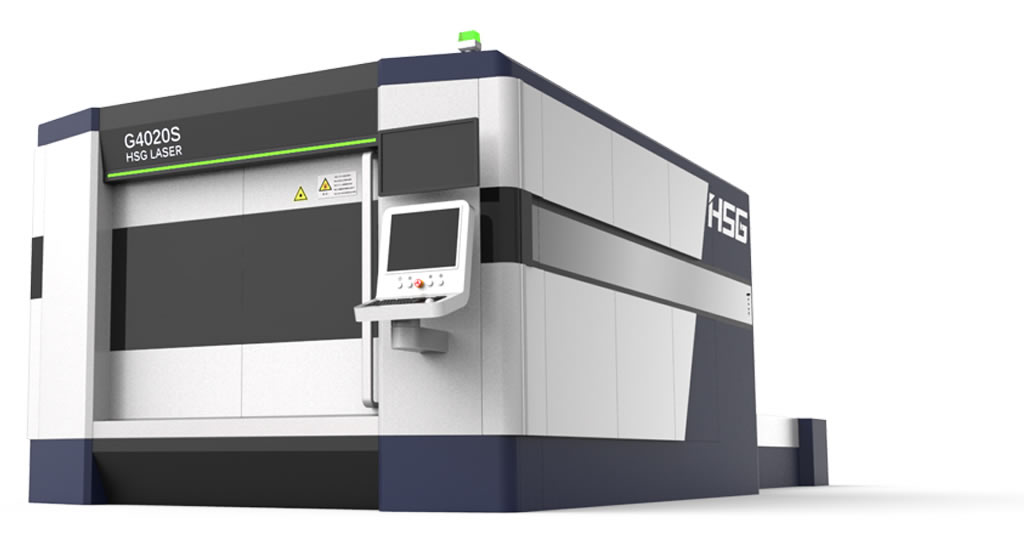

Ultra High Speed laser cutting solution. HSG offers a comprehensive cutting solution.

IPG LASER TECHNOLOGY PLATFORM

IPG LASER TECHNOLOGY PLATFORM

IPG’s unique technology platform allows our products to have higher output powers and superior beam quality at a lower cost than can be achieved by any other competing technology. Our proprietary designs are based around the innovative pumping techniques and high-performance components perfected by IPG over a 20-year period of intense investment and innovation.

Carbon Structural Steel Plate

Made of carbon structural steel plate welding, dislocation nest box construction to avoid welding stress deformation, stress relieved frame at 600℃ high temperature releases annealing stress providing 20 years of normal use without distortion.

Production Description of the of Fiber Machine Chassis:

In the manufacturing process, the CNC machine chassis is first heated to a temperature of 600 °C and then gradually cooled down according to a preset scheme in a cooling container for the period of 24 hours. Its machining is then done in our special 26 ' long milling center. All welds are performed exclusively in a protective atmosphere. This Thermal-Stress Relieving process insures that the frame is free of any deformations and provides the rigidity needed for the highest precision, accuracy and cut quality.

German Alpha Wittenstein

German Alpha Wittenstein

Precision and performance.

The correct rack & precision drive system is an essential component in realizing your machines highest performance and cutting quality. HSG machines offers the finest class of German rack & pinions helical drive systems.

High-performance CNC solution for complex applications

TwinCAT CNC offers complete CNC functionality as a pure PC-based software solution. TwinCAT CNC covers the complete range of classic CNC path control, including high-end systems for complex motion and kinematics requirements. The powerful, continuously evolving PC platform and the hard real-time base of the TwinCAT realtime kernel provide the foundation for the CNC software.

Technical Parameters:

| Sheet Processing Area: | 157.5" x 78.5" |

| Max.Traverse Speed: | 7716 ipm |

| Max. accelerated: | 2.8G |

| X/Y Positioning Accuracy: | ±0.001 " |

| X/Y Repeated Positioning Accuracy: | ±0.001 " |

| Power supply: | 380V 50Hz |

| Laser power: | 4000W-10,000W |

| Laser Source Manufacturer: | IPG |

| Machine Weight: | 39,683 lbs. |

| Machine dimensions: | 453" L x 138" W x 98" H |

| Drive System: | Panasonic Servo Motors |

| Transmission System: | Helical Rack & Pinion (Dual Drive) |

| Graphic Formats: | DXF, PLT, Ai, LXD, GBX, NC G-Code |

| Software: | CypCUT Laser / CypTUBE |

| Machine Cover: | Safety enclosure is standard |

Sheet Processing Area:

Max.Traverse Speed:

Max. Acceleration:

X/Y Positioning Accuracy: ±0.001"

X/Y Repeated Positioning Accuracy: ±0.001"

Power Supply: 380V 50Hz

Laser Power: 4000W-10,000 Watt

Laser Source Manufacturer: IPG

Machine Weight:

Machine Dimensions:

Drive System: Panasonic Servo Motors

Transmission System:

Graphic Formats: DXF, PLT, AI, LXD, GBX, NC G-Code

Software: CypCUT Laser / CypTUBE

Machine Cover: Safety enclosure is standard